Sanand, Ahmedabad, Gujarat

- GST NO. : 24ACKPS9083R1ZH

Fluid Power Actuators

Design |

Design

|

The RC200 is an extremely compact pneumatic actuator. Its scotch yoke design is particularly suited for valves with high start or end torque requirements. It is available in double-acting and spring-returnconfigurations with torque output up to 4,400 Nm (38,000 lbf.in).

|

Pneumatic quarter-turn actuators for demanding applications (10 to 900 Nm)

|

RCC200 firesafe pneumatic quarter-turn actuators (25 to 150 Nm)

|

The K-TORK Range of high-performance ‘true rotary’ vane actuators are used in critical applications commonly found in most process industries. Located in Dallas, Texas, USA, K-TORK products are supplied through the global network of Rotork offices and Rotork agents and K-TORK distributors in the USA. |

K-TORK Air Fail-Safe actuators incorporate an integral air reservoir to fail valve in desired position upon loss of air pressure, electrical power, or both. Available for general purpose or hazardous area classification installations.

|

K-TORK Actuators and Controls represents the future of valve automation. The vane actuator is a ‘True Rotary’ actuator that does not require the conversion of a linear motion to a rotary motion. The result is a simple, highly accurate and reliable quarter-turn pneumatic actuator that is specified for the most demanding process flow control applications.

|

K-TORK offers a de-clutch gearbox manual override that mounts between the actuator and the valve to provide for manual valve operation in the event of air failure or for emergency operation. Under normal automatic operation, the gear is disengaged and the actuator turns freely to operate the valve.

|

The Ranger CG Corrosion-Guard finish greatly extends the life of the actuator in highly-corrosive environments. The housing and vane are treated both inside and out while the Ranger CG system treats all internal threads and cavities. |

Rotork Type K rotary pneumatic damper drives are offered in two basic configurations; the PM Series (Pedestal Mount) and the DM Series (Direct Mount). Both Series provide accurate quarter-turn control to dampers on combustion air and flue gas applications. They offer modulating control, isolation open / close control and bus network control to fit your operating needs.

|

The Type K FasTraK retrofit damper drive has been pre-designed to provide a ready-made product to replace common, older legacy damper drives. After decades of damper drive retrofit, Type K has narrowed and refined the highest volume Series PM (Pedestal Mount) rotary damper drives to provide a Quick Ship upgrade solution. Experience maximum boiler performance with new Type K FasTraK damper drives.

|

The Rotork AH Series high-cycle actuator is ideal for the demanding service found under precipitators on the ash hopper flap gates. The totally-enclose design eliminates the high maintenance cylinder or low-pressure canister actuators.

|

The CT Series linear damper drive was designed specifically for fuel air and auxiliary air applications on CE / Alstom / T-fired / Corner-fired boilers. The CT Series provides excellent and efficient control of the Secondary Air within the windbox and will withstand the extreme heat and vibration common in this application. Effective windbox control will reduce NOx and minimise carbon monoxide (CO) associated with poor fuel-air mixing and will maintain boiler thermal performance.

|

The JR Series was designed specifically for wall-fired boilers with burners using a combination of fuel and combustion air. The JR Series controls the secondary air that is introduced at the burner and the air/fuel ratio is regulated by a sliding-sleeve damper to balance the air flow distribution. The JR Series offers ‘split architecture’ with the Power cylinder and the DPC-777 positioner mounted separately to remove sensitive electronics from the high-temperature area around the boiler and burner. |

The LX Series pneumatic linear damper drive is proven to be the most reliable, robust and premium quality drive for severe duty applications. A properly specified LX Series is capable of operating for millions of cycles in harsh applications with little or no maintenance. |

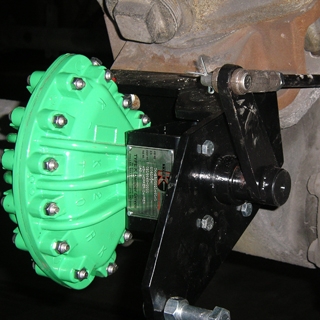

CP range pneumatic actuators are a versatile, modular, scotch yoke design available in both double-acting and spring-return configurations. The compact and efficient design yields high torques even at low pressures. The design concepts found in Rotork's large, heavy-duty actuators has been applied to the CP range, which brings heavy-duty actuator qualities to small, quarter-turn actuators.

|

The 4P/4H multi-turn actuators apply the reliable Planetary Torque Controls System (PTCS), fulfilling requirements in certain industries for actuators with a hydraulic or pneumatic supply in multi-turn applications with position and applied torque control.

|

GP (pneumatic) and GH (hydraulic) range scotch yoke actuators are designed to provide a rotary, quarter-turn movement for either on/off or modulating duty. The rugged yet compact design is available with two different yoke designs. The classic symmetric yoke delivers peak torque at both ends of stroke. Alternatively, they can be supplied with canted torque arms designed to deliver peak torque at only one end of stroke. Use of canted arms can often reduce actuator size, weight and cost for valves with appropriate torque demand characteristics.

|

Rotork linear actuators offer the advantages of compact size, high performance and a simple but highly reliable design. They are ideal for operating on/off and control functions of both globe and wedge gate valves. Both spring-return and double-actingconfigurations are available with either pneumatic or hydraulic cylinders.

|

Rack and pinion actuators often offer the most economical solution for quarter-turn valves that have a fairly constant torque requirement throughout the stroke.

|

RHQ actuators are designed for some of the most challenging valve actuation applications on earth. They are an excellent choice for the demanding requirements and adverse conditions found in applications for mining and offshore. The balanced design has a very compact footprint for a given output. Integral lifting lugs are designed to support the weight of both the actuator and the valve.

|

Contact Us

Chintan Sales

E42 GIDC Estate, Sanand- II, Behind Endurance Technology, BOL GIDC, Taluka: Sanand, Dist.: Ahmedabad - 382170, Sanand, , Gujarat - 380015, India

Call Us : View Mobile Number

Phone : +91-79-26929121, +91-79-48002500

Fax : +91-79-40064060